How to Evaluate Pre-Engineered Building Companies and Manufacturers in India

Shortlisting the right pre engineered building manufacturer is not about chasing the lowest rate per square foot. It is about finding pre engineered building companies that combine strong engineering, in-house fabrication, solid project history, and dependable service. Among so many peb manufacturers in india, you need a simple way to compare options and avoid guesswork. See Our Capabilities

This guide walks through the main checks to evaluate pre engineered building manufacturers in india so you can choose a partner who delivers safe, optimised structures on time, and supports you even after handover.

People often use the words company, manufacturer and supplier as if they are the same. In reality, they can describe very different setups in the PEB world.

Some pre engineered building companies mainly handle coordination. They talk to you, manage drawings and site schedules, but outsource fabrication and sometimes even erection to other firms. True pre engineered building manufacturers own both the design office and the fabrication plant. They employ engineers, detailers, welders and quality teams, and they actually produce your steel components. Then there are pre engineered building suppliers, who usually trade or resell buildings made by other manufacturers, with limited control over engineering or delivery.

For larger or more complex projects, it is generally safer to work directly with a real pre engineered building manufacturer that has in-house design and fabrication. They take responsibility for engineering decisions, quality and timelines instead of passing those risks down a chain of vendors.

Once you are clear about who is a manufacturer and who is only a coordinator or trader, you can start comparing peb manufacturers in india on a few core pillars. Think of this as a scorecard you can use for every vendor.

The first check is always design strength. A serious peb construction company in india will have full-time structural engineers and detailers, not just a single freelancer. They will talk confidently about load calculations, connection design and the codes they follow.

You can ask about their engineers’ qualifications, software (such as STAAD, ETABS or Tekla) and whether they design to relevant Indian standards. Strong engineering means your building will be safe, the steel usage will be optimised, and site changes will be handled with fewer surprises.

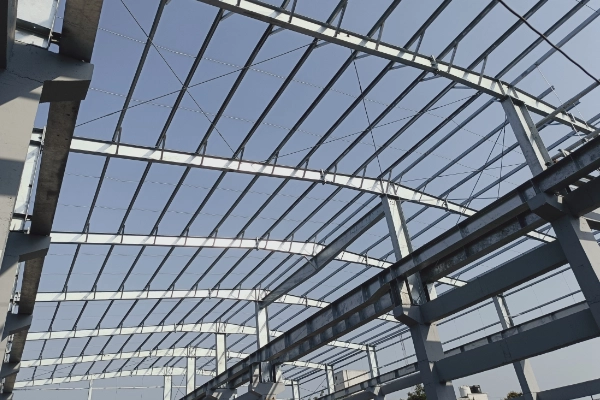

Next, look at the plant. Real pre engineered steel building manufacturers will invite you to see their fabrication setup. You should get a sense of how many metric tonnes they can process in a month, how much covered shed they have, and what kind of machines they use.

Modern equipment like CNC cutting, automatic welding, shot blasting and proper paint booths indicates that they can handle multiple projects in parallel without losing control. A manufacturer whose usual capacity is far below your requirement may struggle to meet your schedule.

Quality is not just a word on a brochure. Leading top pre engineered building manufacturers usually hold formal certifications such as ISO-based systems and can show inspection procedures for raw material, welding, painting and final dispatch.

You can ask if they keep test certificates for steel, if they follow standard welding procedures, and how they inspect structures before sending them to site. Clear answers and documented processes are a good sign. Vague promises without proof are a warning.

Experience is more than just the number of years in business. You want to know how many projects they have actually delivered and in what sectors. When evaluating pre engineered building manufacturers in india, it helps to see total built-up area completed, typical project sizes and a mix of industries served.

If you are building a large warehouse, a manufacturer who has done many similar sheds will be more useful than one who has only handled small canopies. Matching their core experience to your type of project reduces the learning curve and the risk of design or execution mistakes.

Good design and fabrication are important, but your building only comes together at site. Some pre engineered building companies manage erection with their own trained teams. Others work with fixed partners they have used for years. Either way, you need clarity on who will handle erection and how they manage safety and schedules.

You can ask about the number of erection crews, whether you will get a dedicated project manager, and how they plan day-to-day work. Companies that share method statements, basic schedules and safety rules upfront are usually better organised.

Large industrial or logistics projects require the manufacturer to buy steel and other materials in bulk and hold multiple projects at different stages. This demands financial stability. Long-running peb manufacturers in india often mention their years of operation, key clients and repeat business as indirect signals of stability.

For your peace of mind, you can check their company profile, ask about maximum single-project size they have handled and see whether they have delivered multiple large jobs in the same year. A stable partner is less likely to slow down or stop work midway due to cash issues.

Finally, consider how the company communicates and how they handle service after handover. Clear drawings, timely replies to queries and professional documentation make your project easier to control. After the building is ready, there may be minor adjustments, leaks, or future extensions to manage.

A reliable pre engineered building manufacturer will have a simple process for registering service requests, planning visits and supporting additions, rather than leaving you to find new contractors.

Once you send your requirements to several vendors, you will receive a range of quotations. It is tempting to compare only the price per square foot or per tonne. That approach can be misleading.

A better method is to build a simple comparison sheet and list a few key items for each proposal: whether design is included, what grades and thicknesses of steel and sheeting are offered, what is covered in erection, and what timelines and payment terms are proposed. Sometimes a slightly higher price comes with better material, wider scope and a more realistic schedule.

When you evaluate pre engineered building suppliers and manufacturers this way, you see the full picture instead of only the headline number.

While comparing options, there are some warning signs that should make you cautious.

Be careful with pre engineered building companies that do not clearly show a plant address, cannot name actual projects, or rely only on stock photos. Be wary of those who promise extremely short timelines but cannot explain how their capacity supports them. If a company avoids questions about design responsibility or inspection procedures, that is another red flag.

It is reasonable to ask for a plant visit, a list of completed projects and one or two client references. A partner who genuinely has experience will be open to this level of checking.

Modern capacity for parallel projects

Turnkey execution across states

Shree Umiya Structure operates as a full-fledge pre engineered building manufacturer based in Gujarat, with in-house structural design, detailing and fabrication facilities. The team focuses on industrial, warehouse, commercial and infrastructure projects across different states, handling both medium and large-scale jobs as a peb construction company in india.

Over time, the company has delivered sheds and buildings for a range of sectors, combining engineering-led design with organised site execution. For decision-makers looking at multiple pre engineered building companies, this mix of design strength, manufacturing capacity and on-site management makes Shree Umiya a practical option to include on the shortlist. View Projects

If you share your building usage, approximate size, location, crane or mezzanine needs and target completion date, a technical team can prepare a structured proposal and tentative schedule, so you have a concrete basis for comparison.

Share your specs – get a technical proposal and

timeline

from our engineers.

A PEB company may coordinate design and site work but outsource fabrication, while a pre engineered building manufacturer owns the design office and the plant, and actually produces your steel components. Working directly with a manufacturer usually gives better control over quality and timelines.

You can look at years in business, the number and size of projects completed, certifications, and whether they are comfortable with a plant visit. Reliable pre engineered steel building manufacturers also share references and clear technical details instead of staying general.

Not always. A very low quote without clarity on material grades, scope or schedule can lead to thin sections, delays or extra site costs later. It is safer to choose from top pre engineered building manufacturers who explain exactly what they are offering.

You should share building usage, basic dimensions, site location, any crane or mezzanine requirements, expected loading if you know it, and your target completion date. This allows pre engineered building manufacturers in india to estimate tonnage, choose sections and plan timelines realistically.

Yes. Many established peb manufacturers in india execute projects across multiple states using the same design and fabrication base, supported by mobile erection teams and planned logistics. When you evaluate vendors, it helps to ask where they have already delivered similar jobs.

Rajesh

Mehta

Rajesh

Mehta

Rajesh Mehta, Senior Structural Engineer at Shree Umiya Structure Pvt. Ltd., with 12+ years vetting/supervising PEB projects nationwide.